Biscuit production as a business: a list of equipment, a description of the production technology, the nuances of organizing a business. Modern Cookie Business Advertising Cookie Making Business

Free Photos / Pixabay

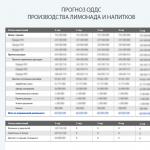

Cookies - small, baked from dough. Various grains are sometimes added to cookie dough; cookies are usually molded in the form of circles, squares, stars, tubules; sometimes cookies are made with a filling (, raisins, cream) or a filling is placed between two cookies.

Biscuit production is an investment-attractive business for a number of reasons: low cost of finished products, stable demand at any time of the year and the ability to constantly make a profit. To assess the effectiveness of investments, it is necessary to study the production process, to assess what costs the purchase of equipment will result in.

How to set up a process

To organize the baking of cookies, knowledge of the technological cycle and production features is not enough. The ultimate goal can be achieved by adhering to the business opening plan:

- Determine the assortment, relying on consumer preferences.

- To study the features of making cookies, decide on the list of equipment, calculate the main costs.

- Rent (buy) a room.

- Form an enterprise.

- Hire staff.

- Set up the production line.

- Organize sales.

The largest material and moral investments will require the launch of a production line, however, it is impossible to select the necessary equipment without first selecting the assortment.

Assortment definition

Cookies belong to flour confectionery. According to GOST R 53041-2008, it can be of various shapes, with or without filling, but one of the prerequisites is that the moisture content is not more than 16%. The main types of cookies are reflected in GOST 24901-2014 “Cookies. General technical conditions". This includes:

- Sugar - a confectionery product characterized by a fragile structure, a flat shape and friability. The mass fraction of sugar in it should not exceed 27%, and the fat content can reach 2-30%. Sugar cookies must be dry, with a mass fraction of moisture not more than 10%. At the discretion of the manufacturer, fillings can be added to it, glazed and given intricate shapes.

- Butter - unlike sugar, it can be voluminous. It is more humid (up to 15.5% moisture), contains at least 30% of products: sugar, fat, eggs and milk (or their substitutes).

- Oatmeal - contains from 14% oatmeal, flakes.

- Protracted. Its feature is the layered structure and the presence of through punctures. The fat content of the product reaches 2-28%, and sugar - no more than 20%.

If we turn to GOST R53041-2008, we can distinguish 3 more types of cookies:

- Layered - 2 or more of any of the above products, held together by filling, finishing or glaze.

- Cracker - unsweetened (up to 10% sugar) dry biscuits (moisture not more than 7%).

- Biscuits are layered cookies with through punctures. Moisture - no more than 11%.

Each type of product has GOST indicators, which means that the proportions of the ingredients used in production must be under strict control.

At first glance, the assortment is limited, but in fact it can be diversified by producing cookies of various shapes, adding inclusions and fillings.

Additives can be small or large. Small - dried fruits and finely ground nuts, cream powder, yogurt powder, ground coffee and others. Large additions - whole or halved nut kernels, raisins, candied fruits, coconut pulp or wafers. The list of additives is determined by the manufacturer's imagination.

The recipes according to which the cookies will be made are drawn up in technological cards, which will require the approval of SanPiN. The standard technological map contains data:

- Business name;

- card number;

- the name of the cookie;

- gross and net consumption rates;

- output of the finished product;

- the source of the prescription;

- description of the technology of preparation, design;

- at the discretion of the technologist - an indication of the nutritional value of 100 g of cookies.

Having determined the assortment, having chosen the priority directions of production for yourself, it is necessary to calculate the costs in accordance with the forthcoming types of work.

However, first of all, it is necessary to legalize the business in order to receive income legally.

Registration of the enterprise

To organize the production of cookies, you need or. If you plan to open a network of bakeries, then it is better to choose an LLC. Documents are submitted to the tax office. One of the important points is the choice of the OKVED code, under which the type of activity is encrypted. For the production of cookies, the code is suitable:

- 10.72 - "Manufacture of crackers, biscuits and other cracked bakery products ... for long-term storage."

Along with registration, you should choose a taxation system. The best option is USN or UTII.

For work, a number of permits should be obtained from the SES and the Ministry of Emergency Situations, taking into account the requirements for the location of production facilities. Working conditions should be clarified in Rospotrebnadzor. Key points - renting a room that is not related to the basement; carrying out repairs that allow disinfection; provide access to running water and communications; maintain optimal temperature and humidity levels in the room.

When renting, you should take into account the size of production facilities, but first you need to decide what equipment is needed for the production of cookies.

Cookie production technology and equipment

Simply put, the cookie production process consists of several successive steps:

Briefly about each of the processes.

Raw material preparation

All ingredients for making cookies must be removed from the container. Solid fats are cleared of plaque. Liquid ingredients are strained. Bulk - flour, sugar, cocoa, coffee and other components necessary according to the recipe are sieved. It is difficult to do this work manually, so I use a flour sifting machine in the production of cookies. It is a unit consisting of a tank for adding ingredients and a spiral system for transfer to a screening system. From the machine, the flour immediately enters a separate tank or dough mixer. The advantage of using a sifter:

- obtaining flour without lumps;

- saturation of the component with oxygen;

- removal of third-party inclusions;

- capturing metal particles with a built-in magnet.

The most commonly used flour sifters are:

- VOSKHOD PVG-600M - vibration type, capable of sifting up to 600 kg of flour per hour. Cost - up to 25 thousand rubles.

- PENZMASH MPM-800M - vibration type with a capacity of up to 500 kg / h. Installation cost - up to 86 thousand rubles.

- DANLER XL-2000 is a powerful auger with screening capacity up to 2000 kg/h. Cost - up to 163 thousand rubles.

Also, attention is paid to the preparation of additives and spices.

After sifting, you can proceed to the next step.

Dough kneading

The dough preparation technology involves the preparation of an emulsion from ingredients: eggs, flour and milk-containing products, water, fats and sugar. After - flour, starch, baking powder are poured.

The properties of the dough depend on the quality of the flour, the physical condition of the fats. Flour with large particles gives a looser, crumbly dough. Fats are recommended to be administered in the form of an emulsion. Enveloping flour particles, they give the dough greater plasticity.

Each type of dough has its own characteristics, which affects the possibility of making cookies of a given shape.

Sugar dough is sweet, which slows down the process of gluten formation. If you use flour with a low gluten content in the production of sugar cookies, the dough will be plastic and less brittle. Consistency allows you to apply a pattern to the surface.

Long dough is also prepared using flour containing a low percentage of gluten. If you take durum flour, the product will turn out to be hard, quickly deformed. Ideally, cookies made from long dough retain their shape for a long time, “spring”, that is, they restore their original appearance after being lightly pressed.

Butter biscuits come in several varieties, and their production is a more labor-intensive process. Cookies are prepared from sweet dough:

- Sand and excavation. To prepare the dough, butter is beaten separately (up to 8 minutes), eggs are shaken with water, and then in emulsion. Flour pours in.

- Sand-jigging - more fatty and moist cookies. For its production, first, a whipped mixture of butter and sugar is prepared (up to 15 minutes) at increasing speed, then the remaining components are added, and at the end - flour.

- Whipped - butter is whipped with powdered sugar, and after 15 minutes. the rest of the ingredients are added.

Product quality control is of particular importance in the production of crackers. They require premium flour with a gluten content of at least 30%, and hard water, with a salt content of about 15 ° F. The use of soft water will negatively affect the quality of the dough: it will become soft, sticky, and difficult to mold. The cracker should be layered, and for this, fats with a melting point of 36 ° C are used. The production of crackers is complicated by the phased production.

At the first, yeast dough is prepared. Fermentation lasts up to 10 hours, and the degree of readiness is determined by measuring the acidity of the dough. At the second stage, kneading is carried out using chemical baking powder, which lasts about an hour. The technologist controls the level of humidity and temperature of the raw material. To reduce the duration of the process, many manufacturers use catalysts for oxidative processes, in particular the drug amylorizine. With it, the fermentation process is reduced by 8-9 hours.

As the analysis of dough manufacturing technology shows, for kneading it is necessary to purchase:

- Planetary mixer. With it, you can knead the dough of a liquid consistency, whip creams and fillings.

- Dough mixing machine - allows you to knead large volumes of a homogeneous mass for making cookies in a matter of minutes. Buying a machine allows you to automate production, since the control is carried out by software.

Approximate cost of mixers:

- RTK 20 - up to 50 thousand rubles. Equipped with speed switch, shutdown sensor. It can be used for making custard, biscuit and shortcrust pastry. Mixer capacity - 20 l.

- GL-SM5.7GR Gemlux - up to 8.5 thousand rubles. More economical, but also less capacious model. The mixer can operate at 6 speeds, and its capacity is up to 5 liters.

Dough mixers:

- YS-W70H-3C GRC is a machine that can knead 70 kg of dough within an hour. Up to 12 kg of dough can be loaded into the machine at one time. The cost of the unit is 65 thousand rubles.

- ТМС-20НН-1Ц Abat - High quality steel mixer with removable bowl. The unit kneads 60 kg of dough per hour, you can load up to 12 kg of pastry or up to 4 kg of hard dough at a time. The cost of the unit is up to 80 thousand rubles.

After kneading, the dough is rolled between the rollers of the dough moulder.

Pumping and aging

Pumping allows all dough components to be evenly distributed in the reservoir. Excess air comes out of the mass. Exhaust dough is subjected to repeated pumping. According to the technological cycle, the draft dough must be aged. As a result, it will turn out crispy, finely porous cookies.

The cost of a dough rolling machine or a "belt conveyor for removing dough pieces" is 100-350 thousand rubles. For example, the Italian model MK600A Mac.Pan will cost 348 thousand rubles. It can roll out layers of 0-38 mm, equipped with anti-stick scrapers.

Product molding

To give the dough a given shape, various cuttings and stamps are used. With the help of them, a pattern is applied to the cookies, they give it a different shape, and the edge of the product is processed. The cost of such installations is from 10 thousand rubles.

Bakery

Perhaps the most important unit in the production of cookies is the oven, but without observing the baking technology, nothing will come of it.

Bringing cookies to readiness is divided into 3 stages. First, high humidity is created in the oven, and the temperature is maintained at 150-160°C. Then the temperature is increased to about 250 ° C, proteins are denatured, and the biscuit rapidly loses moisture. After bringing the product to readiness, the temperature is slowly reduced.

The multi-step process requires the use of reliable equipment to control temperature and humidity levels. For baking cookies, it is necessary to install a system of baking modules, which is a tunnel with a conveyor that feeds a semi-finished product for baking. The cost of installation, for example - MGP-12, reaches 100 thousand rubles. You can get by with baking cabinets that have several compartments for loading products. Popular Models:

- Sunrise KhPE-500 worth up to 45 thousand rubles;

- Kocateq GU6 at a price of up to 126 thousand rubles.

An example of the production of oatmeal cookies:

Finished product packaging

The liver must be provided with appropriate storage conditions, strictly controlling air humidity and temperature. High-quality packaging will ensure the safety of confectionery products and give them a presentable appearance. To do this, you need to purchase a packaging machine. Its cost is about 120 thousand rubles.

In general, the purchase of equipment that ensures the process of making cookies will cost around 800 thousand rubles. However, these are the costs of the main production facilities. This does not include other costs that will become part of the cost of the finished product.

Optional equipment

It is necessary to install a powerful ventilation and air conditioning system, humidity level sensors in the production workshop. The dough and its main ingredients require compliance with storage conditions.

In the hall should be placed:

- refrigeration units for storing ingredients, fillings;

- tables for preparing products for loading onto the production line;

- kitchen tools.

The cost of equipping the premises with auxiliary equipment will amount to 100-150 thousand rubles.

Other costs of the biscuit manufacturer

Purchasing equipment is one of the main tasks for organizing a business. In addition, it is necessary to find the right premises, qualified personnel and a sales market.

Premises for rent

When looking for production space, the length of the production line should be taken into account. Calculations can be carried out independently, based on the parameters of the selected capacities, or you can resort to the help of professionals.

The optimal workshop area is from 100 m2. In addition to the production premises, there should be a warehouse for raw materials and finished products; office space for the work of an accountant, production technologist.

The room must have sewerage, excellent ventilation and a centralized water supply line.

You need to pay attention to the wiring. Most industrial equipment runs on three-phase outlets. Their absence is not critical, but replacing and upgrading wiring will result in additional costs.

It will take up to 150 thousand rubles to prepare the premises for work. The amount includes equipping the premises with washable finishing materials, cosmetic repairs, elimination of defects.

Renting premises on average will be from 80 thousand rubles. per month. Additional payment for utilities - up to 40 thousand rubles. per month.

Recruitment

Food production workers must be professionals, know the technological maps perfectly, work on improving the taste of products.

A prerequisite is the presence of a sanitary book and regular medical examinations in accordance with the established schedule.

A budget of at least 160 thousand rubles should be allocated for the remuneration of personnel (2 operators, a technologist, an accountant, a cleaner).

Raw material

It is better to look for suppliers of raw materials near production. After checking the certificates and personally checking the quality of raw materials, you can conclude supply contracts. The monthly costs for the purchase of the main components of the biscuit depend on the volume of planned production.

On average, the company produces up to 60 tons of cookies per month, while the costs are about 1.8 million rubles. Considering that 1 ton of cookies costs about 38,000 rubles, the income will be 2,280,000 rubles, and the profit will be 480 thousand rubles, which covers the current expenses of the enterprise.

When planning activities, it is necessary to draw up detailed cost estimates according to technological maps, identify reserves for cost reduction and find a permanent sales market.

- Capital investments: 19 350 000 rubles,

- Average monthly revenue: 3 326 400 rubles,

- Net profit: 574,133 rubles,

- Payback: 34 months!

Demand assessment

According to a study conducted by Intesco Research Group in 2010, 847,300 tons of sweet biscuits, waffles, biscuits and gingerbread and similar products were produced in the Russian Federation. There was a noticeable increase in the market compared to 2009, growth rates were at the level of 7.2%. It is expected that in 2011 the market volume will increase by another 2.5%.

According to the study, the demand for biscuits has stimulated new price increases. During 2008-2010 there was a steady increase in producer selling prices for these products. In 2010, the increase in producer prices for biscuits, biscuits and crackers did not exceed 10% on average.

Competition in the market can be described as average. An important role is played by local companies that manufacture products on obsolete Soviet equipment. If you organize production on modern equipment and with competent marketing, you can take a significant share of the market.

1. Business organization

The purpose of writing a business plan: to assess the feasibility of investing in organizing the production of cookies.

1.2. Equipment

After analyzing several proposals from companies involved in the supply of equipment for the production of biscuits, we decided on the proposal of the Russian-Chinese company "Russian-Chinese business center" Cityline ". This company offers a fully automatic line with a capacity of 450 kg. finished products per hour.

On this line, all operations necessary for the manufacture of cookies are performed: from dough kneading to packaging of finished products.

In the biscuit production equipment section, you can find a cheaper option for arranging production.

1.3. Industrial production technology

Basic Operations:

- preparation of raw materials for production;

- dough kneading;

- molding;

- bakery;

- cooling;

- package.

1.4. Premises for the production workshop

To organize the production of cookies on an automatic line, a room with an area of 200 sq.m. (ceiling height 3.5 meters), it is necessary to place a production line, warehouse and amenity premises for personnel in it.

Room requirement:

- The premises must comply with the requirements of SanPiN 2.3.4.551-96

- Presence of water supply and sewerage

- Electricity 380 V

- Convenient transport access.

1.5. Number of staff

With one-shift operation of the confectionery shop, the number of employees is 14 people.

1.6. Markets

According to a study by Intesco Research Group, the distinguishing features of the market is its attachment to the territory, because biscuits have a limited shelf life, and high transportation costs at a low price do not justify the supply of products over long distances.

The rather serious positions of regional market players can be explained by the fact that in each regional center there was a huge number of confectionery factories and bakeries with large capacities, which continue to work even now. In this connection, even small companies that have only one enterprise can become leaders in the segment of inexpensive biscuits by weight.

The share of foreign manufacturers in the segment of biscuits is quite small (about 15%), which can be explained by the peculiarity of the products.

Sales of products can be carried out through the following channels:

- Sales through wholesale companies engaged in the sale of food products

- Sales through regional and federal grocery chains.

2. Feasibility study

2.1. Capital expenditure

2.2. Revenue of the confectionery shop

With one-shift operation of the shop, the maximum output (minus the time for a technical break and a lunch break) per month (22 shifts) is 79.2 tons of cookies.

The wholesale price for 1 ton of cookies starts from 42,000 rubles. Based on the price of 42,000 rubles per 1 ton of finished products and the monthly output of 79.2 tons, the monthly revenue of the confectionery shop is 3,326,400 rubles.

2.3. Cost price

The raw materials for the production of biscuits are flour, granulated sugar, margarine, milk, starch, and other ingredients. For the production of 1 ton of finished products, 1,198 kg of raw materials are required.

2.4. General expenses

2.5 Calculation of profitability

2.6. Payback

The payback period of the confectionery shop is 34 months. This calculation is based on one-shift operation of the shop. If the confectionery shop works in 2-3 shifts, then the payback period will be much shorter.

3. Formal business organization

3.1. Organizational form of activity

For a confectionery shop, the most appropriate organizational form is: "Individual entrepreneur".

3.2. Form of taxation

The optimal form of taxation for the activities of the confectionery shop is a simplified taxation system (income minus expenses). Tax return is submitted once a year (in April).

The following taxes are paid on this system of taxation:

- income tax (15%),

- unified social tax (32%),

- income tax (13%).

Equipment for the production of biscuits AKMALKO ENGINEERING is developed taking into account all the features of the technological processes for the production of various types of biscuits. Depending on the tasks and needs of your production, we can offer you both individual machines and automated lines with different capacities and degrees of automation.

The main semi-finished product in the production of biscuits is dough, which, after kneading, must have certain physical characteristics that allow molding products using equipment for the production of biscuits - the mechanisms of jigging or molding machines. Different types of dough differ in the content of fat and sugar, which affect the processes of swelling of flour proteins. And you can get dough with the necessary parameters of viscosity and elasticity by changing the amount of fat and sugar in the recipe (in combination with other technological factors, for example, dough temperature, humidity and kneading time).

The amount of sugar affects the properties of the dough. The more sugar in the biscuit recipe, the less free water in the liquid phase of the product. It is possible to regulate the processes of swelling of starch and flour proteins by changing the sugar content.

Fats have a direct impact on the processes of dough formation. In this case, an important role is played not only by the chemical composition, but also by the physical state of fats, which must be plastic. Because only in this case, thin films are formed that lubricate and envelop the flour particles.

Plastic fat is a mixture of liquid and solid phases in a certain state. In the production of various varieties of biscuits, the dough recipe contains from 5 to 25% fat relative to the mass of flour. When kneading dough, fats change the properties of wheat starch, prevent swelling of flour proteins and increase the content of the liquid test phase. As a result, the plasticity of the dough increases. If fats are introduced into the dough in the form of an emulsion, their resistance to oxidative processes increases, therefore, the ability to preserve the quality of cookies for a long time increases.

One of the main roles in obtaining a dough with desired properties belongs to the temperature of the batch. With an increase in temperature, processes occur that contribute to the dissolution of crystalline substances and the swelling of flour colloids. Therefore, if it is necessary that the finished dough be plastic, it is recommended to knead it at a low temperature of the raw mixture (19-25°C).

Mixing the recipe components of the dough contributes to the uniform distribution of all ingredients in the dough, as a result of which the semi-finished product becomes homogeneous. The duration of the kneading depends on:

- The quality of flour gluten and its quantity. The duration of kneading increases with an increase in the quality and quantity of flour gluten, since such flour has a high water absorption capacity and a low swelling rate. But in the production of cookies, flour with medium and low gluten is used, and a long kneading of such flour leads to a deterioration in the physical characteristics of the dough.

- The amount of free water. The duration of the dough kneading is inversely proportional to the mass of free water (ceteris paribus).

- Test temperatures. With an increase in the temperature of the semi-finished product, the processes that affect the formation of dough with desired characteristics begin to accelerate. The duration of kneading depends on the type of dough, but, as a rule, it decreases with an increase in its temperature.

Making cookies as a business has its pros and cons. The main plus is the rather large popularity of cookies, which is due to the huge variety of taste, appearance, and price. This makes it more affordable than, for example, various chocolate bars, sweets and pastries. In turn, this makes it possible to reach people with low purchasing power. In addition, modern society tends to purchase more natural products that do not contain a large number of additives, dyes and various substitutes. This fact makes this product even more popular among buyers.

Another important plus of this enterprise is the quick payback of the cost of equipment, as well as the costs of maintaining and servicing the production line. The main disadvantage of such a business is a fairly high level of competition in this market segment. However, even small enterprises can compete with well-known, more popular confectionery manufacturers. This is primarily due to the fact that new production facilities use the latest technologies and equipment, which makes it possible to reduce costs while maintaining the proper quality of the product, and also creatively approach the production process, constantly expanding and updating the range. To the minuses, you can add the rather large advertising costs that are needed to promote the product to the market.

Step by step opening plan

You should start by studying the demand for products, that is, what kind of cookies and in what pricing policy is most in demand. Based on this, equipment and technology for the manufacture of cookies will be selected in the future. Then, when there is an approximate vision of the final product, we take the following steps:

- Choice of equipment and equipment;

- Manufacturing technology;

- Selection of buildings, premises;

- Personnel, its number;

- Sales channels for finished products.

How much can you earn

When working 22 days in one shift, the monthly amount of cookies made will be 79.2 tons. The selling price of one ton of the product in bulk starts from 42 thousand rubles. This means that the monthly revenue will be about 3,326,400 rubles.

How much money do you need to start a business

Capital investments will be:

- Units and equipment for the production line - 13.5 million rubles;

- Transportation, installation and adjustment of equipment - 2.35 million rubles;

- Current costs (advertising, supply of raw materials, etc.) - 3.5 million rubles.

Total: 19.35 million rubles

Investments in production per month:

- Remuneration of employees - 278 thousand rubles.

- For renting buildings, hangars - 200 thousand rubles.

- Advertising campaigns - 50 thousand rubles.

- Transportation costs - 100 thousand rubles.

- Communal - 10 thousand rubles.

- Outsourcing-accounting - 25 thousand rubles.

- Other expenses - 35 thousand rubles.

Total: 698 thousand rubles

To produce 1 ton of product, 1.2 tons of ingredients (flour, fat, sugar, dairy products, starch, etc.) are needed. The cost per shift is 4.28 tons of raw materials, at a cost of 75,827 rubles, and for 22 working days - 1,668,190 rubles. Electricity costs 9,492 rubles per day, and 284,760 rubles for twenty-two days. Thus, the cost of cookies: for one day - 85,319 rubles, for the working days of the month - 1,952,950 rubles.

Income without paying taxes - 675,450 rubles. Minus 15% of the tax, equal to 101,318 rubles, we get a net benefit - 574,133 rubles.

What equipment to choose for the manufacture of the product

The following equipment is used:

- Z-shaped dough mixer (for making non-yeast, shortbread, sourdough, dumplings, hard dough (for bagels), etc.) Includes kuvette for kneading, lid and Z-shaped blades. Dough mixers are of two types - with a jacket (for cooling / heating the mass) and without it. There is an adjustment of the speed of the blades.

- If molding is not done by hand, then a molding machine is needed.

- Special equipment for processing the top of cookies. For example, for glazing.

- The oven itself, preferably with fast heating, a high-quality turntable, a door with a hermetic and heat-resistant sealing gasket, with lighting inside the chamber.

- Packing device. Packaging can be in bags of 200-300-500 grams or in cardboard packaging for sale by weight.

You will also need a flour sifter, refrigerators, dough machines.

What OKVED for business

Such a business is classified as manufacturing. For the operation of the biscuit production workshop, code 10.72 - Production of crackers, biscuits and other rusk bakery products, and so on, is required, namely item 10.72.31, which is responsible for the production of biscuits.

What documents are needed to open

To organize a mini-enterprise, it will be enough to open an individual business. You will need: a passport, an application for state registration, a receipt for payment of state duty, a copy of the TIN certificate.

What system of taxation to choose for production

The most suitable option is individual entrepreneurship (IP) with a simplified taxation system (simplified).

Do I need permission to open

To organize production, it will be necessary to comply with SanPiN and SNiP standards in preparing the premises, equipping the workshop, setting up and operating equipment, storing raw materials and finished products.

Production technology

The main steps in making cookies include:

- Preparation of raw materials and all components.

- Test batch.

- Cookie mold.

- Product baking.

- Cooling and packaging of products.

How to calculate the required investment

In order to objectively assess the required cash investments, the number of required personnel, the likely income, the payback period of production, a carefully thought-out business plan is required.

First of all, it is necessary to conduct market research to find out the most popular types of these products, to calculate what price competitors have set for them. It must be made lower than that of other manufacturers. To do this, it is imperative to purchase the most modern and best equipment for the production of cookies.

Due to its high cost, many firms are trying to save on labor automation. Although if you need to set up the production of various types of goods, then a fully automatic biscuit production line will pay off with sufficient loading of the workshop in 6-8 months.

For the production of biscuits on an automated production line, a workshop with an area of at least 200 m², with a ceiling height of 3-5 m is required. It will house the production line, warehouses and amenity rooms for staff. They must necessarily comply with SanPiN 2.3.4.551-96. They must have water supply and 380 V electricity. At the same time, one should not forget about the obligatory convenient access for transport. It is necessary to locate a workshop near the sales area, since cookies have a limited shelf life, and high transportation costs at a low price of products cannot pay for their delivery over long distances.

The subtleties of the cookie business

It is worth considering a few more aspects, such as the sales market and the range of goods. A distinctive feature of this production is its territorial attachment to a certain region, and due to the unprofitability of delivering confectionery products over long distances, the share of foreign cookies in the market is rather small. This enables even a small company that has only 1 workshop to become a leader in the segment of inexpensive biscuits by weight. In this regard, you need to sell your products:

- through regional and federal grocery chains;

- through wholesale companies specializing in the delivery and sale of various food products to the nearest chains of stores and supermarkets.

Do not forget about the range of products. It should be large enough, as this will attract as many buyers as possible and make even more profit. The range of products needs to be constantly expanded. It is necessary to constantly monitor the market in order to find out what is now the most in demand and what features of the product will give the greatest influx of buyers. For example, products without various chemical additives are now gaining popularity, so it is beneficial to start making cookies without preservatives, flavors, and dyes. There is a growing demand for biscuits with biologically active additives and dietary ones.

Criteria for calculating the profitability of making cookies

Based on the above features of this type of business, we can conclude what exactly you should pay attention to when creating a business plan. The main point is technical and economic calculations, which combine the calculation of cash investments. For example, for the purchase of equipment, the construction and arrangement of a workshop. Do not forget about the calculation of the revenue of the confectionery shop, because it depends on how soon your investment will pay off and how profitable your business will be.

Another important point is the calculation of the cost of the product: the lower it is, the more profit the workshop will bring and the lower the market value can be set. This will help you beat your competitors and attract even more customers.

Do not forget about the calculation of the total cost of maintaining the enterprise, paying salaries to workers, repair and marketing costs.

The last point greatly affects the price and profitability of the business. Attention should be paid to automation: this will help reduce the number of employees. You should not save on reliable equipment, because the less breakdowns occur in production, the more efficient and cost-effective it is. The price of equipment is one of the biggest expenses for those who start a biscuit business.

Marketing is a very important expense as it helps to attract more customers and increase cookie sales. Do not forget about the calculation of the expected profit that you can get if you open a cookie production. This will allow you to calculate the payback period for this business.

According to experts, the payback period for a confectionery shop equipped with an automatic line is 34 months. At the same time, this period can be reduced if the workshop works in 2-3 shifts.

Cookies belong to one of the varieties of confectionery, therefore it is very popular. This sweet treat was enjoyed by both children and adults. It is bought not only for home tea drinking, but also when they go to visit as a small present for the festive table. Given the popularity of the sweet product, you can safely start building your own business in this area. The first stage is the production of biscuits with all items of expenditure and the expected profitability.

To have a constant profit, you do not need to organize an enterprise on a large scale. Very successfully uses a small production. One of the aspects of the right direction will be high-quality, tasty and diverse products at affordable prices for consumers. Also, various novelties are attracting great attention, with which the entrepreneur will increase and expand the range of his products.

After some time, mini-production will gain momentum and turn into a worthy enterprise with a high income. A well-thought-out biscuit business plan has the following points:

All important points cannot be ignored. If all issues are considered at the highest level at a businessman's enterprise, then there will only be an established production of high quality products.

Production technology

Almost all types of cookies have an identical cooking technology. The difference is only in the raw composition of the mixture and additional ingredients. For the manufacture of cookies you will need products:

- sugar

- flavor additives

- fillers

It is best to purchase products in bulk, so the entrepreneur will be able to save some money that he will need for other purposes.

Very important: raw materials for biscuits as storage must have proper conditions. Failure to follow the rules leads to rapid deterioration of the ingredients.

The average scheme for manufacturing products includes the following steps:

Cookies can be packed in containers or special food boxes. It depends on the wishes and requests of the client.

The process of making cookies is automated, but there are some types of products that require only manual action. This refers to the exclusive form of cookies on order. Only a true professional can create your own confectionery masterpiece, so include only experienced staff in your staffing table.

Cookies according to their recipe are:

- sand

- biscuit

- biscuit

- cottage cheese

- exhaust

- puff

Transmission on how to open a cookie production:

Also, in some types of cookies, additives in the form of chocolate, nuts, candied fruits, raisins, confiture, dried apricots, and coconut flakes are used.

Each consumer has different preferences, but in this case, the product range will play an important role. In any case, you will not go wrong with different types of confectionery, because the demand for delicious pastries is always stable.

How to organize the sale of products

After completing all the points of the business plan for the production of cookies, it's time to think about the market for your confectionery. If there are no people willing to buy your products, then there will be no income. The entire structure of the business is based on the result of generating income.

Some simple tips will help you quickly find your customers, who can easily be turned into potential leads (Table 1).

Some simple tips will help you quickly find your customers, who can easily be turned into potential leads (Table 1).

Successful action | Description |

Study the customer demand of competitors and evaluate their product range | Several types of products are sure to be especially popular, so pay attention to them. Offer your exclusive variant of confectionery baking. |

Include new types in your assortment every time | People are always eager to try something new, and if they like it the first time, consider that you have found your regular customers. |

Consider your region | Based on how you draw up a business plan for the production of cookies, and what products you offer. |

Draw up contracts with wholesale buyers in stores, supermarkets or food depots | Strong connections will help you to constantly sell your products and occupy a worthy niche in the market. |

Purchase of equipment

For the production of cookies in large quantities, you need to use the necessary equipment. What should be in the enterprise:

Modern enterprises have installed automatic lines with well-established technical characteristics. Thanks to automation, it is possible to reduce some costs and speed up the process of making cookies. And this key point does not distort the taste at the output of the product.

The price for the purchase of automated equipment is high, but according to expert estimates, saving on this item is not worth it. And if for the first time in your plans to work only with a certain type of product, the equipment should be as a line with high productivity.

Production room

Before setting up a serial production of products, you should prepare a room for these purposes. Strict requirements are constantly applied to the arrangement of the workshop.

The smallest workshop can be placed on the territory of 120-150 m2. This area is only enough to produce a certain batch of products. The installation and subsequent start-up of the entire production line must be taken into account, so expect a space of at least 200 m2.

Also, in your premises there must be a special place allocated for a warehouse of finished products, change houses and a dining room for staff.

Also, in your premises there must be a special place allocated for a warehouse of finished products, change houses and a dining room for staff.

The premises must be provided with means of communication (water, electricity, sewerage).

Without all these components, not a single fire service will sign you a permit to operate the premises. And do not forget about convenient and uncluttered access roads to your premises.

Hiring

The confectionery shop, despite its automatic equipment, cannot exist without a certain number of personnel:

A one-shift work schedule requires at least 14 people for a small production. The salary must be set according to the position held.

Capital expenditures

When opening your own business, you need to be prepared for the fact that at the initial level capital investments will be large. And so the payback period will take some time.

Starting investments will be required:

Starting investments will be required:

- rent or purchase of premises

- purchase of equipment

- automatic line setup

- purchase of raw materials and other components

Estimated revenue

It is possible to determine the main indicator of profit, taking into account the scale of production and the number of products produced per work shift.

For an illustrative example:

The amount of profit will be obtained taking into account expenses and income received.

The sale of biscuits in any area occupies a leading position. The main thing is to attract sweet lovers with its assortment and recipe.

Product cost calculation

The valuation of expenses is obvious when calculating how much money needs to be invested in opening a workshop. It includes an expense item:

- Purchase of equipment

- Production registration

- Purchase of raw materials and auxiliary ingredients

- Communal payments

- Premises for rent

Other items of expenditure are included in fixed expenses for each month.

Monthly expenses

This item of expenditure may vary, and depends on the volume of production and the number of staff. It includes:

- purchase of raw materials

- repair and adjustment of equipment

- staff salaries

- fare

- paying utility bills

All points are interconnected with each other and pursue a single goal - the production of quality products on high terms.

Payback period

Quick profit depends on many factors. The main ones are:

- range of finished products

- number of products produced per month

- fast implementation

In the initial months of production, it is too early to talk about payback periods, but if the enterprise gains momentum, then experts in this field indicate a period of 1 year or more.

To speed up the process, you can organize the baking of confectionery products according to a 2- or 3-shift work schedule. This is a function to allow you to make a profit in an accelerated mode.

To speed up the process, you can organize the baking of confectionery products according to a 2- or 3-shift work schedule. This is a function to allow you to make a profit in an accelerated mode.

What form of business to choose

In the legal field, you can organize two ways:

- IP is a simple form for small businesses.

- LLC is a complicated form for legal entities.

Although, the second method is more conducive to cooperation with business partners. In addition, banks issue loans with a loyal interest to a legal entity without problems and with great confidence.

Company taxation

The most important point for filing documents with the tax organization is taxation. There is a simplified taxation system (Article 346.13, paragraph 4), and it implies a payment of 15% of the difference between income received and expenses for the production of confectionery products.

For start-up businessmen, paying 6% of the amount of net profit will be a profitable option.

For start-up businessmen, paying 6% of the amount of net profit will be a profitable option.

Despite the high competition in the confectionery segment, many aspiring entrepreneurs are not afraid to introduce new developments in the sweet business. Delicious and high-quality products will always find a place in the market and win undeniable authority from their consumers.

Write your question in the form below