How to open a lemonade production. Profitability and Efficiency of Lemonade Production in a Mini Plant

Engineering LLC sells complex lemonade bottling lines designed according to individual specifications of manufacturing plants. We produce turnkey equipment for factories, from beverage production technology to bottle, cork, label design, selection of equipment for water treatment, CO 2 bottleless supply, shelving equipment for a warehouse. Our clients can order a bottling line for lemonade or mineral water, we will do all the work for the client. All you have to do is sign the contract and make the payment.

To order a conveyor:

Design of a lemonade production workshop

To buy a bottling line, it is necessary to determine the equipment with which it will be equipped. To select equipment for a lemonade machine and calculate equipment for the production of water and its bottling, it is necessary to agree on the initial data and fill out a questionnaire, which will be the basis of the terms of reference, as well as provide the following information:

- project or plan of the existing premises where water production is planned;

- points of supply of water, electricity, compressed air, sewerage;

- storage areas for the placement of consumables, finished products, administrative and service premises;

- the planned productivity of the water preparation and bottling shop;

- wishes for the placement of the main and auxiliary equipment.

After providing the initial data, you can select the optimal equipment. Having made a calculation, the engineers draw up a project and send it for approval to the client, where the lemonade production line will be given in detail. After the signing of the contract and the project, the stage of production and delivery begins.

Lemonade bottling line configuration

An example of a production line in the minimum configuration:

- Complex for the production of PET bottles with a capacity of 3,000 - 20,000 bottles per hour.

- Pneumatic conveyor for feeding empty bottles to the filling triblock.

- Filling triblock: rinsing - filling - capping.

- Mixer-saturator for the preparation of the finished drink.

- Labeling machine for sticking polypropylene labels.

- Packaging machine in shrink film.

- Conveyors for moving bottles in the bottling line.

- Control cabinet for the lemonade bottling line.

- Pallet wrapper.

- Date printer.

This package may include a saturator and a packer from stock or made to order. If it is necessary to automate the production process, the line is equipped with conveyors and accumulation tables with the organization of production without the participation of an operator.

It is possible to expand the complete set of the workshop with a boiler for preparing syrup and a bottle rinser. Additional equipment may include:

- vertical conveyor for lifting to the upper floors;

- dater for putting down the date of manufacture;

- labeler for labeling;

- a set of water treatment and filtration equipment;

- conveyors;

- accumulation tables;

- palletizer.

The basic configuration of the lemonade bottling line can include:

- blending department for preparing an assortment of drinks;

- system for the preparation of sanitary solutions;

- compressor equipment;

- equipment for balloon-free enrichment of lemonade with carbon dioxide;

- water treatment system;

- refrigerator for cooling the drink before bottling;

- vertical conveyor for lifting or lowering products to different floors.

The cost of a lemonade and mineral water plant directly depends on the configuration, productivity and degree of automation of the process for mini lemonade production or other variations. The less operator intervention is required in the production process, the more expensive the automation of production.

Mini-production of lemonade can be safely called a promising area for small business. This is evidenced by statistics: over the past four years, the volume of production of a sweet drink has increased by 30%. This is due to the growing demand for soft drinks…

The volume of consumption of draft lemonade is growing, which is sold in specialized stores and in trade stalls on the streets in the summer (along with kvass). Therefore, the mini-factory has several options for marketing products at once: producing a drink in small containers for deliveries to grocery stores and bottling lemonade into bulk kegs for delivery to cafes, street outlets and draft beer stores.

The portal website will tell you how to organize your own production of a sweet drink in a mini-production environment.

Premises - where to locate the production

The production of lemonade belongs to the food industry, so quite serious requirements are imposed on the premises. It is impossible to open production in close proximity to industrial enterprises, in basement workshops and in places where it is impossible to bring the appropriate communications.

The room itself must be at least 150 square meters. m. Only to accommodate one production line, it will take about 50 square meters. m., and you also need to allocate space for a warehouse of raw materials and a warehouse for finished products, for a staff room, for an office and a utility block.

Technology decides

The first thing to do in the first place is to develop a recipe for lemonade. And not just one, but several varieties at once. This issue needs to be resolved in advance, since it will take weeks, or even months, to work out the optimal taste. Here you can not do without an experienced technologist.

The recipe for lemonade includes such components as: flavors, sweeteners, dyes, sodium benzoate, citric acid, carbon dioxide, drinking water. The output should be lemonade according to GOST 28188-89.

You look at such a composition, and you will not want to drink. But you can’t get away: without adding these components, the drink will turn out to be tasteless and with a short shelf life.

Equipment selection is not an easy task

Depending on the goals of the company, the approximate set of equipment for launching the line is as follows:

- Saturation plant - designed to saturate the drink with carbon dioxide.

- Water treatment system - designed to purify water from heavy metals (mercury, zinc, iron, manganese), microbes, odors, particles and organic substances.

- Syrup preparation station - a capacity of several thousand liters.

- Bottling unit - designed for pouring lemonade into PET or glass containers.

- Capping machine – used for capping PET and glass bottles with stoppers.

- The PET bottle blowing machine is designed for the preparation of containers for beverages.

- Labeling machine - applies company labels to bottles.

You can also install a triblock: rinsing + bottling + corking. In this case, the number of separate machines for the production of lemonade will be noticeably reduced. For example, the bottling unit YUVEST 4.0 BNT (Orelpischemash) produces up to 4,000 bottles per hour. This is a fairly productive machine, but you can find an option with smaller production volumes.

Separately, it is worth mentioning about the blow molding machine. For a mini - plant, the purchase of such an apparatus is optional. A blow molding machine is required only for large volumes. At the initial stage, when full-fledged sales have not yet been established, the best option would be to buy ready-made containers. This has its drawback: a large number of bottles will require appropriate storage space. Or you will have to establish almost daily supplies of containers.

Suppliers will give you detailed advice on the choice of equipment. They are obliged to provide all the technical documentation for the devices, and in some cases - to carry out installation and commissioning at their own expense.

The total cost of purchasing equipment is difficult to calculate. It all depends on the configuration, the declared volumes, the condition of the equipment (new or used) and other points. One thing is for sure: the business will not be limited to one million.

Much depends on the choice of the line supplier. It's good that there are some options here. You can buy foreign equipment. Turnkey mini-factories are offered by Italian and Chinese suppliers. European equipment is expensive because it is of high quality. China, on the other hand, offers relatively cheap lines, but is not responsible for the quality. The golden mean is the acquisition of a domestic line. The well-known company LLC PKTs Orelpischemash produces a whole series of various machines for the production of lemonade, from saturators to capacitive and packaging equipment.

The positive side of cooperation with a Russian supplier is that it is easier to carry out warranty repairs of equipment. And this is a very important point, since, in the event of a line shutdown, the urgency of its repair will be of decisive importance.

It will also be necessary to establish supplies of finished PET bottles or PET preforms. A preform is a blank for a future bottle. Buying a preform is preferable because the cost of packaging is reduced. It is smaller than a finished bottle and takes up less space, resulting in lower transport costs and reduced storage space. But you will need to purchase a blow molding machine that will produce a finished container from the preform.

Organizational moments

To produce lemonade, you will need to register a business, obtain certificates for the production of soft drinks (“vanilla”, “pinocchio”, “pear”, etc.) or a declaration of conformity. For detailed advice, please contact your local branch of Rospotrebnadzor. A sanitary and epidemiological conclusion is also issued there, allowing the release of the drink.

Without these documents, it is impossible to arrange the sale of lemonade through stores and retail chains. And the start-up mini-factory does not need problems with regulatory authorities (production may be considered illegal).

Brief calculation of the profitability of the enterprise

The costs of the enterprise, with a capacity of 240 thousand liters of lemonade per month:

- Room rental - 30,000 rubles.

- The salary of operators (3 people) - 90,000 rubles.

- Salary of office workers (accountant, sales and marketing managers) - 120,000 rubles.

- Handymen and warehouse workers (3 people) - 60,000 rubles.

- Security - 35,000 rubles.

- Utilities (water, electricity) - 50,000 rubles.

- Materials (PET containers) - 480,000 rubles. (2.0 rub/piece)

- Raw materials (citric acid, sweeteners and other ingredients) - 1,500,000 rubles.

- Transportation costs - 50,000 rubles.

- Taxes - 15,000 rubles.

- Other expenses (overalls, gloves, unforeseen expenses, etc.) - 50,000 rubles.

Total - 2,480,000 rubles.

The cost of production of one liter of lemonade is 10.33 rubles.

Monthly income:

The manufacturer's margin is at least 30%. Therefore, the selling price of one liter of lemonade will be equal to 13.43 rubles. Income from one liter will be 3.10 rubles. If you sell the entire volume of manufactured products (240 thousand liters), then the monthly profit will be 744,000 rubles.

The article describes the nuances of the business of soft drinks on the example lemonade business plan. This drink is always in demand, especially in summer, it has a wide range of marketing options - kegs, plastic and glass bottles.

The competition in the soft drinks market is very high. In addition to well-known world brands, there are a large number of small players on it, producing, however, not always high-quality goods. If you plan to produce real lemonade according to traditional recipes, and not chemically tinted soda, then the chances of success and capturing your market share are very high.

Key Features of a Lemonade and Beverage Production Business Plan

PURPOSE OF THE LEMONADE PRODUCTION BUSINESS PLAN

The production of carbonated soft drinks does not require a complex multi-component technological process; in this case, we can say that the simpler the better if natural ingredients are used. However, in addition to the recipe, there are many important things that must be implemented both before the launch of the project, and at the stage of its preparation. For a full description of the whole complex of events, we use business plan for the production of lemonade.

It will outline all stages of the project, describe all the processes and factors that affect the success of the business, such as market conditions, competitive advantages of the product, technologies and equipment used, personnel issues and financial and economic indicators used to calculate profitability.

Description

Files

ESSENCE OF THE PROJECT

The project provides for the launch of an enterprise for the production and bottling of lemonade for sale in the form of kegs, for bottling, and as a bottled drink in plastic and glass bottles of various sizes. The main consumer segment is, of course, children, but during the summer periods, the demand for the drink is growing in all consumer segments.

The enterprise requires certain equipment and the availability of buildings and workshops for technological processes, but the manufacturing procedure itself is quite simple. To quickly launch production, you need to follow the logic of the business and consistently implement all its stages.

Our business plan lemonade production summarizes the following steps:

- preparation of the raw material base for the manufacture of the drink and its bottling;

- lemonade production;

- packaging and delivery to consumers.

A high-quality drink, using natural ingredients and observing technology, will always find its buyer even in a highly competitive market.

1 - Summary

1.1. The essence of the project

1.2. The volume of investments to launch the production of lemonade and drinks

1.3. Work results

2 - Concept

2.1. Project concept

2.2. Description/Properties/Characteristics

2.3. Goals for 5 years

3 - Market

3.1. Market size

3.2. Market Dynamics

4 - Staff

4.1. staffing

4.2. Processes

4.3. Wage

5 - Financial plan

5.1. Investment plan

5.2. Funding Plan

5.3. Lemonade and Beverage Production Development Sales Plan

5.4. Spending plan

5.5. Tax payment plan

5.6. Reports

5.7. Investor income

6 - Analysis

6.1. Investment analysis

6.2. The financial analysis

6.3. Risks of Lemonade and Beverage Production

7 - Conclusions

The business plan for the production of lemonade and drinks is provided in MS Word format - it already has all the tables, graphs, diagrams and descriptions. You can use them "as is" because it's ready to use. Or you can adjust any section for yourself.

For example: if you need to change the name of the project or the region where the business is located, then this is easy to do in the "Project Concept" section.

Financial calculations are provided in MS Excel format - parameters are highlighted in the financial model - this means that you can change any parameter, and the model will automatically calculate everything: it will build all tables, graphs and charts.

For example: if you need to increase the sales plan, then it is enough to change the sales volume for a given product (service) - the model will recalculate everything automatically, and all tables and charts will be ready immediately: monthly sales plan, sales structure, sales dynamics - all this will be ready .

A feature of the financial model is that all formulas, parameters and variables are available for change, which means that any specialist who knows how to work in MS Excel can adjust the model for themselves.

Rates

Feedback from our clients

Feedback on the business plan of the brewery for the production of beer

To start the brewery, it was necessary to attract external investments, and we decided that a credit line in our case would be the best solution. After preliminary negotiations with Sberbank, we formed a list of necessary documents that needed to be prepared. Among the requirements of the bank was both a business plan and a financial model for the production of beer. Having studied various developers of business plans, we settled on Plan-Pro for two reasons: first, we liked the quality of execution of ready-made business plans, second, the financial model seemed to us quite thoughtful and understandable, plus the bank said that such a level of study project is more than enough. As a result: our brewery received a bank loan in the amount of 250 million rubles. Thank you, because thanks to the painstaking work of developing a business plan and making adjustments, we received approval for a loan. Thank you for your turnkey work!

Stepan Nikolaevich, owner of the Stary Klyon brewery, Tyumen

Feedback on the business plan for the production of confectionery

Our confectionery shop has risen to the challenge of the times and we need additional investment. At first, we did not consider the possibility of ordering a ready-made business plan and wanted to do everything ourselves. But it turned out to be a difficult task to make a good business plan from scratch, so we bought a ready-made solution on the website to use it as the basis for our production. We did the right thing: thanks to the high-quality work of the site, investors did not have any unnecessary questions, and we received an investment in the amount of 40 million rubles.

Maria Mikhailovna, Tomsk bakery

Feedback on a business plan for the production of compound feed with subsequent sale

Our organization needed a business plan for two purposes: we were evaluating the profitability of a compound feed business and we wanted to raise external funding. After looking at the various business plans of the feed mill on the net, we settled on the Plan-Pro project. As a result, we were satisfied with the result and got exactly what we needed: a ready-made business plan with a clear structure, a financial model for the development of a mixed feed plant, which is quite easy to change for ourselves.

Lyudmila Tsvetkova, financial director, Voronezh

THE SEQUENCE OF FORMING A BUSINESS PLAN FOR THE PRODUCTION OF LEMONADE

Achieving the goals of the project and its economic efficiency requires careful study of all sections.

SUBJECT OF PLANNING

Shop for the production and bottling of lemonade for the sale of draft and bottled drinks on the market with the release of finished products of XXX liters per day.

STRUCTURE OF A LEMONADE PRODUCTION BUSINESS PLAN

Lemonade production, like any other business process, requires compliance with a certain structure and procedure described in the relevant sections business plan:

- research of market conditions, main players, determination of the target consumer and the characteristics of the product of interest to him;

- determination of the amount of investment investments for a successful start with a list of cost items;

- description of the circle of potential investors;

- technological process characteristics;

- planned profitability indicators and their structure;

- HR block;

- promotion and marketing policy;

- section with economic and financial performance indicators of the project.

MARKET CONDITION

This section of the lemonade business plan will be fundamental in all further development and planning processes. As a result of the compilation, we will get a vision of our product, the factors of its success in the market and the distinctive characteristics that affect the choice of buyers.

Advantages of our lemonade in comparison with competitors:

- a minimum of chemical additives and flavor enhancers - only natural raw materials;

- a variety of forms of release and types of containers;

- competitive price;

- professional merchandising and marketing support.

Another good business option is jam production. characterizes this direction. In modern conditions, this format of activity can become very relevant and in demand by consumers.

ORGANIZATIONAL MOMENTS OF LAUNCHING LEMONADE PRODUCTION

In order to achieve all planned indicators, a large amount of preparatory organizational and administrative work is needed. Then our lemonade business plan will be implemented promptly and without downtime caused by shortcomings in the organization of the process. What need to do:

- Register your business in the form of a legal entity or an individual entrepreneur.

- Register with the tax authorities and select a bank that services your settlements.

- Determine the location for the location of the enterprise, taking into account the logistics component of the project.

- Study the technology and select the necessary equipment.

- Determine the sources for finding employees.

INVESTMENT AMOUNT FOR STARTING AN ENTERPRISE

Having an idea for implementation is not always the key to the success of a future enterprise. It is necessary to find sources of funding, which is often the most difficult task. To speed up its solution, download a sample from our website. lemonade business plan which contains calculations necessary for assessing the profitability of financial indicators and will allow you to significantly simplify the search for potential investors.

Our project will require the following investments in preparation for launch:

- repair and re-equipment of buildings and structures - XXX rubles;

- acquisition and installation of a manufacturing and bottling line - XXX rubles;

- formation of stocks of raw materials - XXX rubles;

- a program to promote a new brand and the cost of building a distribution network - XXX rubles;

- recruitment costs - XXX rubles;

- other costs not included in the project (force majeure) - XXX rubles;

The volume of investments will be from 50 to 120 million rubles.

SUBTLETS OF THE LEMONAD PRODUCTION PROCESS AND THEIR REFLECTION IN THE BUSINESS PLAN

The entire production cycle consists of several stages: formulation development, in accordance with GOST, preparation and softening of water, its carbonation and mixing with the raw material base to give color and taste, cooling and bottling of the finished product.

The technological line, its composition and cost must be indicated in:

- filtration plant for water treatment and purification;

- apparatus for carbonation;

- syrup mixing and preparation line;

- equipment for bottling and capping finished products;

- marking equipment for labeling;

- refrigeration units;

- racks and loaders.

ECONOMIC JUSTIFICATION OF THE PROJECT EFFICIENCY

OPERATING COSTS IN THE LEMONAD PRODUCTION BUSINESS PLAN

Any operational activity requires constant financial support of all processes. IN lemonade business plan it is necessary to indicate all operating expenses, in accordance with the main items of the balance sheet, and evaluate their impact on the overall profitability of the project.

Expenditure items:

- payment for the cost of using the premises of the enterprise - XXX rubles;

- purchase of raw components of the drink - XXX rubles;

- payment of the cost of energy resources and utility costs - XXX rubles;

- repair and maintenance of the technological line - XXX rubles;

- transportation costs - XXX rubles;

- advertising and distribution - XXX rubles;

- funds for wages and deductions from them - XXX rubles;

- tax payments - XXX rub.

- other expenses - XXX p.

In total, current activities require monthly expenses in the amount of XXX rubles.

PLANNING REVENUE AND PROFITABILITY OF PRODUCTS

Revenue is formed in the process of sales, respectively, we manage sales, and we manage revenue. Therefore, when drawing up a business plan for the production of lemonade, it is important to describe in detail the factors that form sales and the share of types of drinks in total sales.

The profitability of the project will depend on:

- ensuring the required amount of demand, taking into account the seasonal component;

- use of all distribution opportunities, especially during summer periods;

- compliance with GOST and a unique recipe;

- competitive price.

Sales structure:

- Draft lemonade - XXX rub.

- Bottled lemonade - XXX rub.

Sales revenue will be XXX rubles.

HR ISSUES IN THE LEMONAD PRODUCTION BUSINESS PLAN

For most enterprises, the quality of management and staffing are key success factors. Employees who are qualified, understand their motivations and genuinely love their work are a valuable commercial resource.

IN lemonade business plan describes the required staff minimum, indicating the position and amount of remuneration, in order to organize the smooth and efficient operation of the enterprise.

We will need:

- enterprise manager - XXX rubles;

- process engineer - XXX rubles;

- accounting - 2 people. - XXX rub.;

- personnel department - 2 people. - XXX rub.;

- workers - 10 people. - XXX rub.;

- drivers - 2 people. - XXX rub.;

- cleaners and loaders - 4 people. - XXX rub.;

- marketing and sales department - 4 people. - XXX rub.

PROJECT PROFITABILITY AND PAYBACK CALCULATION

Taking into account the sales proceeds, initial investments and operating expenses, the payback period will be from 3 to 5 years. indicators. Each of the parameters of the financial model can be changed manually.

A necessary component of a full-fledged business plan is a flexible sales plan. It is important, on the one hand, to have a forecast for the business as a whole, and on the other hand, to be able to see the profitability in the context of a separate profit center or even a separate product.

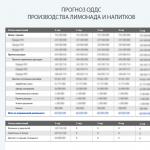

The cash flow statement is the most important document of any business plan. It contains comprehensive information about the operating, investment and financial inflows and outflows of the company, and also allows you to evaluate the overall picture of the company's performance.

BENEFITS OF PROFESSIONAL BUSINESS PLANNING

The market economy and the level of competition in the soft drinks market forces entrepreneurs to find new ideas and ways to implement them in order to be successful and make a profit. One of the tools for achieving goals will be a well-developed business plan. Unfortunately, the formalization of the project takes a lot of time and effort, not to mention the specifics of the financial and economic part.

To shorten the path to leadership, download a full-fledged ready-made lemonade business plan, in which all the main financial and economic indicators are structured. You can also order an individual turnkey business plan that takes into account all aspects of your particular business. This will give you an advantage in project launch time and allow you to increase the efficiency of your new business.

Refreshments are popular among consumers and there will always be connoisseurs of traditional lemonade in this market. To get ahead of your competitors and realize your strengths and opportunities, use the services of professionals and make your business plan a 100% working document.

1) Classic technology for the production of lemonade. Lemonade is made by mixing lemon tincture, apple juice, and coller (burnt sugar, which is dark brown in color, giving the lemonade a yellowish tint). After that, the drink is saturated.

Other types of lemonade are made in a similar way. Mint and lime tinctures are used for mojito, pear tinctures are used for duchesse, and extragon tincture (aromatic medicinal plant) is used for tarragon.

2) Flavored lemonade production technology. Lemonade is made by mixing natural or nature-identical flavors, citric acid, sugar and E150d color (Caramel Coller).

In terms of taste, they are currently difficult to distinguish from natural ones, and the production process is much simpler. There is no need to burn sugar to give color and prepare tinctures.

Other types of lemonades (Duchess, tarragon, mojito) are produced in a similar way, only the appropriate flavorings and dyes are used, for example, for tarragon - dye R100 (Green Apple).

The shelf life of the finished product is 2-6 months.

3) Technology for the production of lemonade with the addition of natural juice. Lemonade is produced according to the classical or flavoring technology, but with the addition of natural juice. This gives lemonade its zest and more interesting taste. If you pay attention, similar lemonades are sold in stores (they usually write on the label: with the addition of natural juice) and they have a more interesting and natural taste.

We do not describe here the entire line of lemonades (barberry, bluebell, cream soda ...), but only those that are in demand. The production technology is similar for everyone, so we classify them into one group.

Lemonades are the only drinks that are quite competitive even produced without the use of natural raw materials. Those. it is quite possible to produce flavored lemonade, it will be in demand and you can make money on it.

This page is under construction, we apologize. Photos and videos will come later.

If you look at it, there is a certain common sense in this, and the benefits of natural lemonade are considerable. After all, potassium citrate, contained in lemonade, dissolves kidney stones well - scientists have conducted a number of studies confirming this fact. .

In principle, lemonade can be made at home. It is made from citric acid and sugar, as well as from a composition based on color, lemon tincture and apple juice. The drink has a refreshing taste, yellow color and smell of lemon oils. Most often, a business in the production and sale of lemonade, as a related area, is practiced by enterprises producing non-alcoholic products and breweries.

Why lemonade will always be relevant?

Children are known to carefully observe the behavior of adults. They are not averse to sitting in the park and drinking beer on warm summer evenings. The child, looking at their example, also most likely wants to drink a glass of some drink. Homemade milk is gradually boring, but lemonade is quite an attractive product. In addition, each child has its own specific taste, so the seller must offer lemonade options with different ones.

In addition, mom and dad can also, looking at the child, buy a glass of sweet drink. However, it should be understood that 90% of all lemonade is sold during the summer season.

In winter, it is sold rather sluggishly, so excessive production of the drink during this season is likely to result in losses. In addition, the beauty of lemonade lies in its coolness, which is unlikely to be relevant in a cold winter. You need to understand that a mother who is worried about the health of her child is unlikely to buy her child a glass of cold lemonade in the winter cold. This also applies to adults. During the cold seasons, they practically do not drink anything outside the house.

Recipe and preparation

Classic lemonade has a fairly simple recipe. First, pour about 300 grams of lemon juice into a large container. After that, about 1.5 liters of distilled water and 50 grams of sugar are added here. Once the sugar is completely dissolved, the tincture can be further diluted with water. The disadvantage is that the independent production of lemonade cannot compete with large-scale production. After all, natural lemonades are not cheap and are practically absent on the market. The lemonade factory produces artificial lemonades that can be stored for months. In addition, you need to understand that lemonade belongs to the range of drinks, like other popular soft drinks.

Equipment for the sale of lemonade

Nothing special is required to produce lemonade. Equipment for the sale of lemonade, similar to the one on which kvass is produced. For example, to sell kvass, you need:

- refrigerator, in case bottled kvass is sold;

- automatic filling rack;

- stock of KEG (some of them should be in operation, the second part is needed to exchange for new ones);

- stock of disposable cups with a volume of 0.2-0.5 l, special PET packaging.

For those who prefer to sell using vending machines (vending), you should focus on investments of about 100,000 rubles for one vending machine. Obviously, not everyone can afford such a cost of equipment. The device already has devices for accepting money, and is also capable of pouring lemonade into cups.

In addition, "advanced" vending machines for business have the ability to send both SMS messages using a GSM modem and email messages using a GPRS modem. The devices are loaded by means of two KEGs with a volume of 30-50 liters.

Where is the best place to sell lemonade?

Since lemonade is mainly drunk by children, therefore, the point of sale of the drink should be installed on the beach, in the park, in a shopping center or cinema. These are exactly the places where parents bring their children. However, the best place to sell lemonade is not far from the cafe. In this case, you can save a lot on organizing your own small food business.

This applies to both money and nerves. It is much easier to negotiate with the owner of a cafe than with the director of a shopping center or cinema. Of course, you will have to share some of the profits with him, but he is able to protect you from unexpected police raids or inspections. The owner of the cafe can simply say that you are working on behalf of his enterprise. In addition, a working cafe means the presence of customers.

This is much better than standing at the end of the park, where passers-by rarely go, and admiring the certificate of registration of an individual entrepreneur, instead of counting profits. If you decide to work independently, study the sanitary requirements in the field of food circulation. In addition, you will need to be puzzled by the issue of obtaining a sanitary book, permission from Rospotrebnadzor, and deal with tax accounting.

Apparatus for production

In order to start making your own lemonade, you need to purchase equipment for the production of lemonade. First of all, we are talking about a syrup boiler with a volume of 5 cubic meters (5000 l). It must have sufficient thermal insulation, have two layers. If necessary, the lemonade production line can be equipped with a screw conveyor. It is made of stainless steel, has an unloading unit and a drive with closed bearing units.

For syrup, it is also recommended to buy a plate filter. In addition, ingredients and syrup need their own containers. The production technology also requires a cold installation, preferably as many as two. Their productivity should be at least 6-7 cubic meters per hour. All this equipment is controlled by a single remote control. Your mini production shop will also require the purchase of several cooling circuits.

Production technology

Ready lemonade is based on a mixture of all its components. The blend is recommended to be made using the cold method, however, semi-hot and hot methods are now increasingly common. Do not forget that the taste and quality of the final product is determined by the quality of each of its components. So don't skimp on the ingredients. Otherwise, lemonade will simply cease to be sold.

A business plan for the production of lemonade should also include the search for quality water suppliers. After all, it makes up at least 95% of the total volume of this refreshing and tasty drink. On the territory of large lemonade manufacturing plants, there are often springs or wells with high-quality fresh water. However, no matter how good the water is, it needs mandatory filtration. The freshness and cooling effect is achieved due to the presence of CO2, or carbon monoxide, in the water.

As for the profitability of the business, we will give a review of the distributor of fresh juice and lemonade in Anapa. “... I don’t know how things are with lemonade in other places, but I have a constant rush (the point is located at the entrance to the beach). Kegs are delivered and changed almost every hour. The income is considerable, but the expenses are also impressive, renting a place is the most expensive. Net profit is about 50-60,000 rubles per month (beach season) .. "Therefore, it's up to you whether it's profitable or not.